Contract manufacturing of electronics

Development steps

Idea of the future product

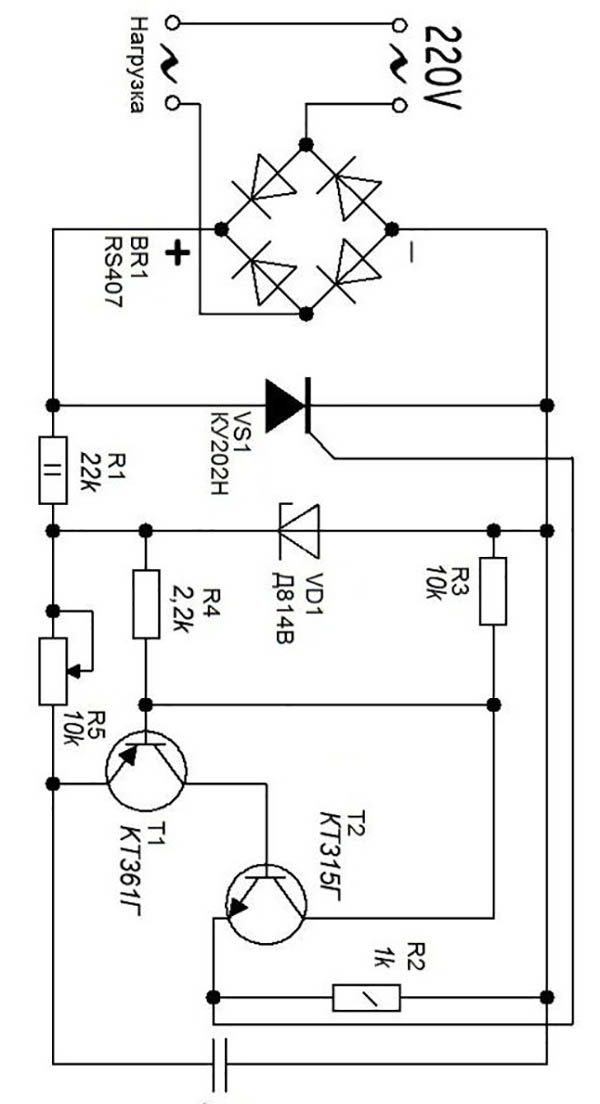

One of the first stages is the creation of an electrical circuit and specifications, according to which in the future our design engineers will be able to competently design the layout of the board and prepare the necessary documentation for the manufacture of the board. At this stage, all the technical characteristics of your future product are laid down. In the layout of the board for automatic installation, it is necessary to comply with all production requirements:

- set the correct dimensions of the contact pads recommended by the manufacturer of electronic components;

- mask over vias;

- setting technological fields and fiducial marks.

You can learn more about the work at this stage by clicking on the link:

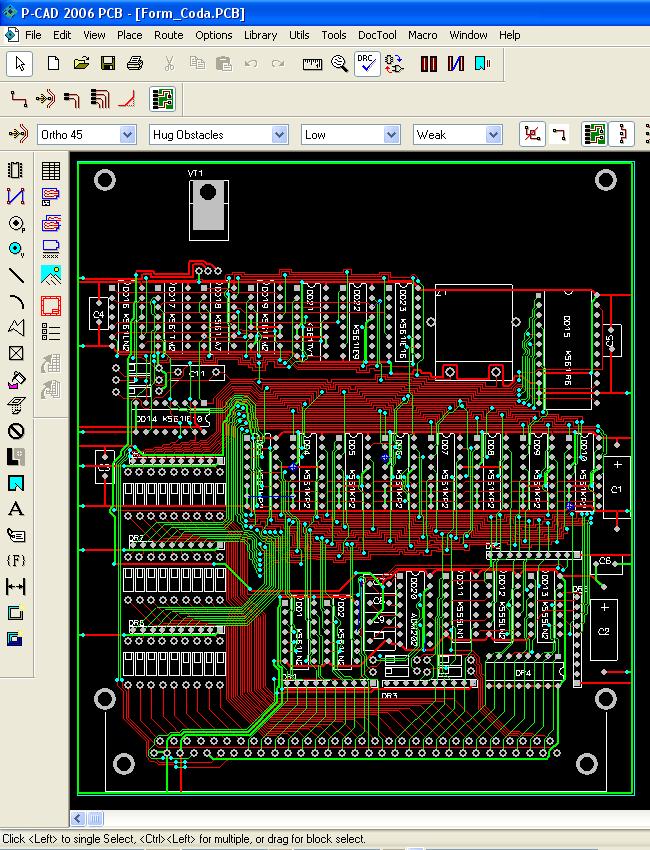

Gerber file creation

According to the schematic diagram and specification, a gerber file is produced for the manufacture of a printed circuit board of a future product. More information about the process of designing and manufacturing printed circuit boards can be found by clicking on the link:

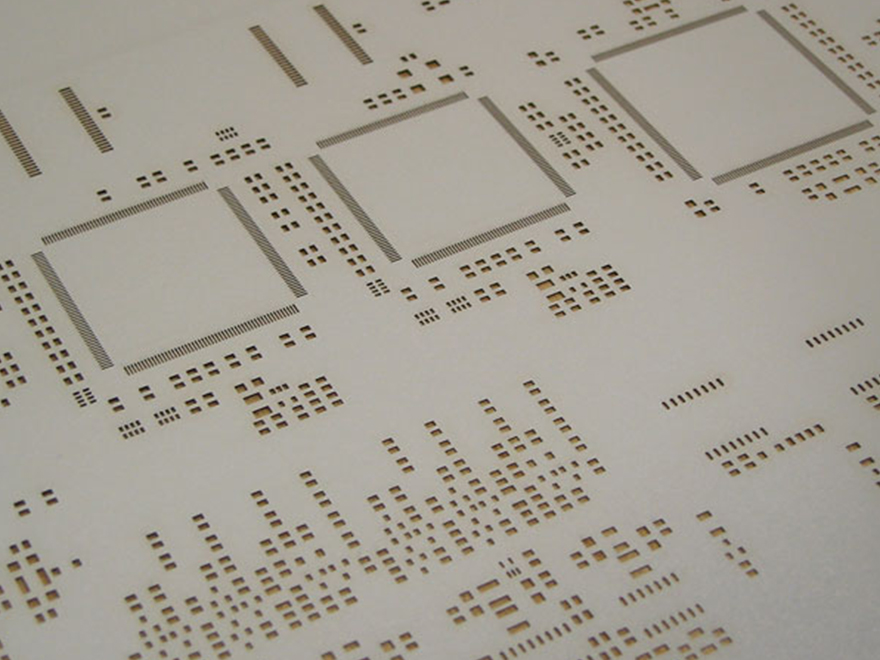

Making a stencil

Parallel to the PCB fabrication process, a stencil is produced for automatic mounting of components. For automatic installation, the following requirements are required:

- a border around the perimeter;

- thickness no more than 0.1mm;

- material – stainless steel.

Writing a program

After reviewing the documentation, the line operator writes a program to place the components. An important role is played by the correctness of the documentation and the correctly compiled pick&place of the location of the components on the printed circuit board

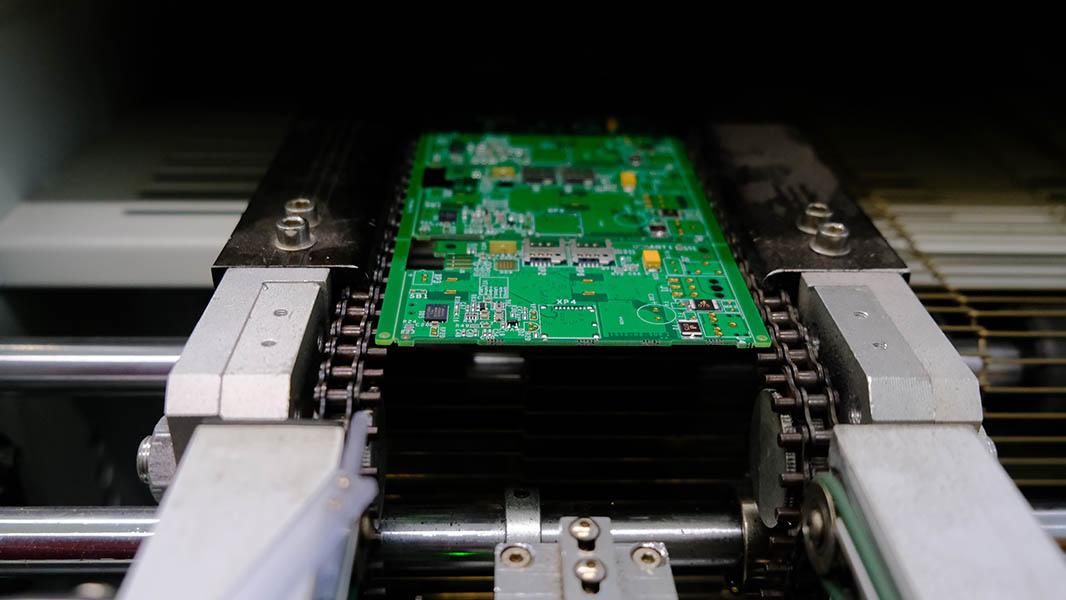

SMD montage

First, solder paste is applied to the board by screen printing, which speeds up the soldering process, which is especially important for complex printed circuit boards. The paste also acts as a degreaser. The components are loaded by the line operator into the machines for installing smd-components in accordance with the previously agreed design documentation. An important role in this is played by the quality of the packaging of the components (the components must be on reels, in pallets), as well as the condition of the components (the contacts of the components must be free of oxides). You can read more about the smd installation process by clicking on the link:

Convection soldering

PCBs with installed components are placed in convection high temperature reflow ovens from manufacturers such as NEODEN (T12L) and ALLSMT (easyFlow 6/30). All furnaces are equipped with 12 heaters in 6 reflow zones and a sectional cooling zone.

The production is equipped with three such furnaces, which allows you to speed up the soldering of printed circuit boards.

Technical control №1

After the smd – installation of components is made, the boards are automatically inspected for the correct installation of the components, and the quality of their soldering is also checked.

DIP editing

After the inspection, the output components are dip-mounted according to the design and assembly documentation. Installation of specific components, screwing of radiators, soldering of wires is possible.

Wash and Dry

After installation work, all boards are washed in an ultrasonic bath to remove solder and flux residues, using a special Kyzen shampoo.

This important stage in production ensures the quality of your products.

The correct fluid temperature and frequency of cleaning is important. In our production, there are three such bathtubs with a volume of 100L each

After washing, printed circuit boards are dried in an oven.

Technical control №2

All boards are visually carefully checked by specialists for soldering quality.

At the request of the customer, the boards can be varnished, filled with compound or vixint. It is also possible to electrically test your products, flash the program, install modules in cases (we can also prepare cases for assembly, carry out metalwork and milling work on plastic) and final assembly of the finished product, packaging.

More information about the sealing of modules, products, printed circuit boards can be found by clicking on the link:

Equipment

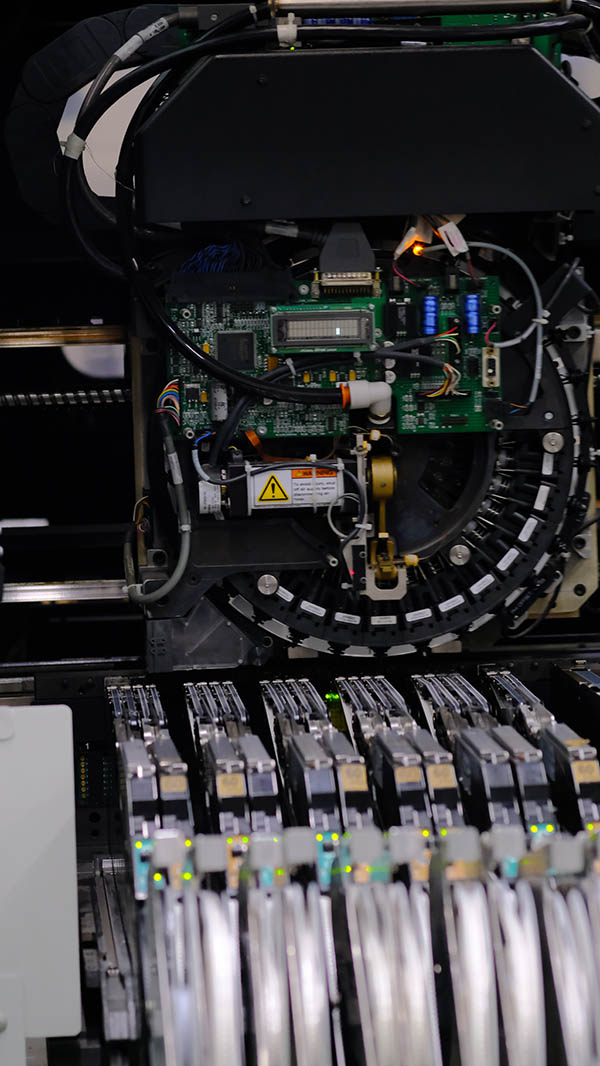

Three lines for automatic installation of SMD components from one of the world’s largest equipment manufacturers Universal Instruments Corporation (USA) are installed at the production site. AdvantisV series models: AC-30L, AC-72 – 2pcs, AC-60D, are equipped with advanced technical solutions to ensure stable performance in mass production.

AdvantisV AC-30L

AdvantisV AC-72

AdvantisV AC-60D

Also in production, an improved high-speed NeoDen (K1830) is used, which has 8 setting heads with a high accuracy of 0.01mm.

NeoDen (K1830)

Three high temperature reflow convection ovens from NEODEN (T12L) and ALLSMT (easyFlow 6/30). All furnaces are equipped with 12 heaters in 6 reflow zones and a sectional cooling zone.

ALLSMT Easy Flow630

NEODEN T12L

Cost

The cost of contract manufacturing of electronics consists of the cost of production stages, in relation to the designed product. We do not take into account project management work, revisions of technical documentation and the labor costs of our group of development engineers when drawing up estimates for the development of a module, unit, product.

To determine the cost of contract manufacturing, we recommend contacting our manager.